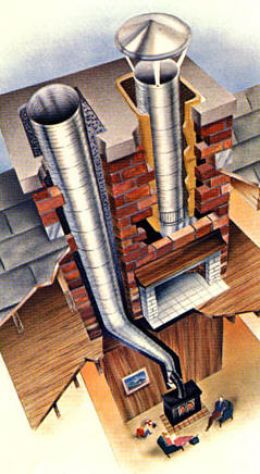

To answer this, we’ll first define what a “flue” is: A flue is a duct, pipe, or opening in a chimney for conveying exhaust gases from a fireplace, furnace, water heater, boiler, or generator to the outdoors. Historically the term flue meant the chimney itself.

A chimney liner is a clay, ceramic or metal conduit installed inside of a chimney to contain combustion products, direct them to the outside atmosphere, and protect the chimney walls from heat and corrosion.

Unlined chimneys transfer heat so quickly that nearby combustibles are at risk of catching fire.

Flue gases are acidic by nature and can eat away at the mortar joints from inside the chimney. As these joints erode, heat transfers more rapidly to the nearby combustibles and dangerous gases such as carbon monoxide can leak inside of the home.

With the correct size flue, appliances such as furnaces, boilers, water heaters, etc. receive the correct amount of combustion air while still allowing the passage of combustion products.

While the requirements for chimney liners differ between states and cities, it is good practice to always make sure your flue liner is up to date. If yours cracks or is corroded, it can allow dangerous gases to enter your home, therefore endangering you and your family. It can also put your home at risk of catching fire.

The most cost-effective solution is using a metal chimney liner. The installation is fairly simple and isn’t terribly expensive. Clay can be less effective and have the risk of corroding at the mortar joints which can lead to expensive installation costs. Cast-in-place liners can be very expensive and if done imperfectly can lead to even larger problems down the line.

We tend to require chimney liner installation whenever we are doing a replacement furnace or water heater to ensure the effectiveness of the new equipment and the safety of our customers.